HMNB Devonport Thanckes Oil Fuel Jetty

Thanckes Oil Fuel Depot sits on the River Tamar opposite the north yard of HMNB Devonport, Plymouth. The existing Yonderberry Jetty is nearly 70 years old and needs replacing and updating to provide a modern facility for fuelling Royal Navy vessels.

Purpose

Given the facility holds up to 138,000m3 of high flashpoint fuel, new pipelines and fire-fighting systems are also needed to comply with stringent standards and health and safety regulations, including the Control of Major Accident Hazards (COMAH) Regulations.

What we did

We are designing and constructing a new jetty, fuel pipelines and tank fire-fighting system. Once the new jetty is commissioned, its adjacent predecessor, Yonderberry Jetty, will be decommissioned and demolished.

The new 260m-long jetty comprises tubular piles, precast concrete beams, and an in-situ concrete deck. Working from crane barges, we installed 68 percussive and 15 drilled piles, before placing precast concrete units and stitching the structure together with infill in-situ concrete pours. We adapted an existing piling gate to enable two piles to be installed safely from one jack-up barge location, saving time and money. We have equipped the jetty with mooring dolphins, a vessel pedestrian access brow, a refuelling pontoon for small craft, and a new crew transfer pontoon.

Mechanical and electrical works include installing a telescopic loading crane, marine loading arms for the transfer of six different types of fuel, and fuel lines stretching the length of the new jetty bank to the existing tank farm. Landside, we installed an 11kv high voltage line, fibre optics, SCADA, earthing, communications, and associated infrastructure.

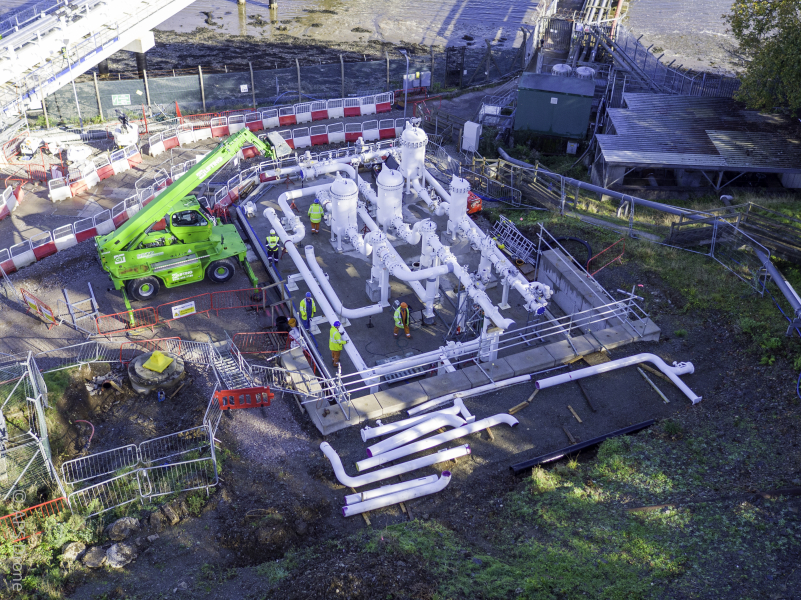

We are replacing the existing firefighting system by installing 3km of buried and 500m of above-ground pipework, 24 hydrants, eight tank drenching systems, two 27m-diameter storage tanks and 2km of controls and power ducting.

Project successes

We are delivering upgrades that will allow the continued safe operation of a vital defence facility. We worked collaboratively as a design, construction, customer and stakeholder team to plan the works and meet the rigorous standards of the COMAH Regulations.

We secured a Considerate Constructors Scheme Certificate of Excellence. The scheme commits sites to respect the community, care for the environment and value their workforce. We met a higher standard than is typically witnessed on defence projects away from the gaze of the public. The assessor was particularly impressed with our behavioural safety programme, including initiatives such as injury awareness and plant-people interface workshops.